Introduction to the Tesla LFP Battery Factory Nevada

The Tesla LFP battery factory Nevada marks a bold step in America’s push for clean energy. This new site in Sparks, Nevada, focuses on making lithium iron phosphate (LFP) batteries right here at home. These batteries power Tesla’s popular energy storage products and could soon help electric vehicles (EVs) go further for less money.

Why does this matter? For years, most LFP batteries came from overseas, mostly China. Now, with tariffs rising and supply chains shaky, Tesla is building its own factory next to the massive Gigafactory Nevada. This move creates jobs, cuts costs, and makes green tech more reliable. In this guide, we’ll break down what LFP batteries are, how the factory works, and why it changes the game for everyday folks like you who want cleaner air and cheaper power.

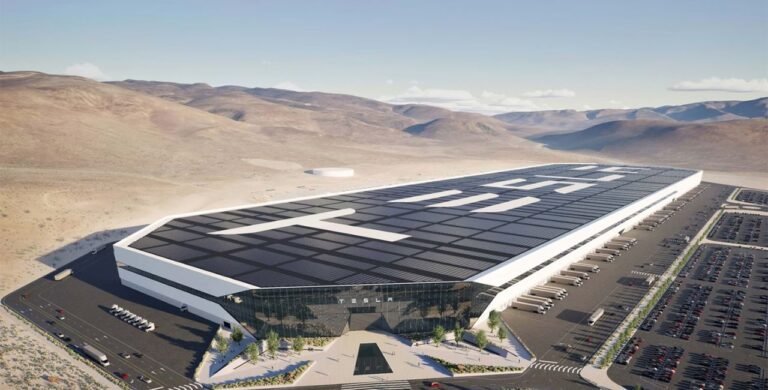

The Tesla LFP battery factory Nevada isn’t just a building—it’s a hub for innovation. It started taking shape in early 2024, with plans to crank out cells by late 2025. Tesla shared drone videos in June 2025 showing the site nearly done. Early output? About 10 gigawatt-hours (GWh) a year, enough for thousands of home Powerwalls or utility-scale Megapacks. That’s a big win for Nevada’s economy, adding hundreds of skilled jobs in battery tech.

What Are LFP Batteries and Why Choose Them?

LFP stands for lithium iron phosphate. These batteries use iron and phosphate instead of pricey metals like nickel or cobalt. That makes them simpler to make and kinder to the planet.

Here’s a quick list of why LFP shines:

- Safer: Less heat buildup means lower fire risk—great for homes and grids.

- Longer Life: They handle 3,000+ charge cycles, outlasting many rivals by double.

- Cheaper: No rare metals keep costs down, often 20-30% less than nickel-based options.

- Eco-Friendly: Mining iron is easier and greener than cobalt, which often involves tough labor issues abroad.

Tesla picked LFP for its standard-range Model 3 and Model Y in places like China. But in the US, import rules and taxes made it tricky. That’s where the Tesla LFP battery factory Nevada steps in. It uses a “wet coating” process, a tried-and-true method for even electrode layers. This tech comes from gear bought from CATL, the world’s top battery maker, but Tesla runs the show 100%.

Fun fact: LFP batteries love full charges. Tesla says charge your LFP Model 3 to 100% daily—no babying needed. This factory will make cells that last, helping families save on power bills year after year.

A Quick Look at Gigafactory Nevada’s History

Gigafactory Nevada kicked off in 2014 as Tesla’s first big battery plant. Back then, it teamed up with Panasonic to make cells for early EVs. The site, east of Reno in Storey County, spans millions of square feet. It now pumps out billions of cells yearly for motors, packs, and storage.

Fast-forward to 2025: The factory has grown huge. It hit 39 GWh capacity last year alone. But Tesla needed more for its booming energy biz. Enter the Tesla LFP battery factory Nevada—a dedicated wing for LFP cells. It’s not replacing the main lines; it’s adding them. Panasonic still handles nickel cells nearby, while this spot focuses on LFP for storage first.

Nevada won the bid over states like Texas because of quick permits and tax breaks. Governor Brian Sandoval called it a “historic day” back in 2014. Today, it employs over 7,000 folks, with 3,000 more spots opening soon from expansions like this LFP site. Check out Tesla’s career page for Nevada jobs to see openings in battery assembly and quality control.

This factory builds on wins like the Powerwall launch in 2016. It proves Tesla’s knack for scaling green tech fast.

Inside the Tesla LFP Battery Factory Nevada: How It Works

Step inside the Tesla LFP battery factory Nevada, and you see robots humming, conveyor belts whirring, and teams in clean suits testing cells. The process starts with raw materials: lithium, iron, and phosphate salts mixed into slurries.

Here’s a simple breakdown of key steps:

- Electrode Coating: Slurry spreads thin on metal foils using the wet method. Dry it, and you get cathodes and anodes.

- Cell Assembly: Stack or wind the layers, add separators, and seal in pouches or prisms. Tesla goes prismatic here—boxy shapes that pack tight.

- Formation and Testing: Charge the cells slowly to “form” them, then zap with heat and cycles to check safety.

- Packing: Ship ready cells to lines for Megapacks or Powerwalls.

The factory uses CATL’s older machines, tweaked for Tesla’s speed. It’s small-scale at first—10 GWh/year—but that’s smart. It lets them learn without big risks. By 2026, output could double as demand grows.

Safety first: The site has fire suppression and air filters to keep things clean. Workers train on everything from forklift ops to defect spotting. Tesla posts 34+ jobs now, from techs to engineers, paying solid wages in Reno’s growing hub.

This setup cuts shipping woes. Cells made here reach assembly lines in days, not weeks.

Why the Tesla LFP Battery Factory Nevada Matters for Energy Storage

Energy storage is exploding. In Q1 2025, Tesla deployed 10.4 GWh of Megapacks and Powerwalls—up from 4 GWh the year before. That’s enough to power small towns. But grids need stability for solar and wind. LFP cells fit perfect: cheap, tough, and steady.

The Tesla LFP battery factory Nevada feeds this boom. Its first cells go to Megapacks—giant units for utilities. One Megapack holds 3.9 MWh, enough for 3,600 homes daily. With local LFP, Tesla dodges 25% tariffs on Chinese imports, saving millions.

Take California: Blackouts hit hard in heat waves. Megapacks with Nevada LFP could store midday sun power for evenings. Or think farms—Powerwalls let ranchers run pumps off-grid, slashing diesel use.

Stats show the shift: Global LFP demand hits 1,200 GWh by 2030, per BloombergNEF. Tesla’s slice? Growing fast, thanks to this factory. It also qualifies for US tax credits, making installs cheaper for buyers.

Pro tip: If you’re eyeing a Powerwall, wait for Q1 2026. Nevada cells mean faster installs and lower prices.

Jobs and Community Boost from the Tesla LFP Battery Factory Nevada

Building the Tesla LFP battery factory Nevada isn’t just about batteries—it’s about people. The site adds 500+ direct jobs by 2026, from line workers ($25/hour entry) to process engineers ($100K+). Indirect gigs? Think truckers, suppliers, and cafes in Sparks.

Nevada’s unemployment dipped to 4.2% in 2025, partly from Tesla’s pull. The factory trains locals via Reno’s community colleges—free courses in welding and robotics. One worker shared: “I went from retail to running cell testers in six months. Tesla changed my life.”

Communities win too. Tesla funds schools and parks in Storey County, where population jumped 20% since 2014. The factory runs on solar—its roof sprouts panels for net-zero power.

For job hunters: Skills like basic math and teamwork matter most. No degree? No problem—apply via Tesla’s Nevada careers. It’s a ladder up in green jobs.

Challenges and Wins: Domestic LFP Production Hurdles

Going local sounds great, but it’s not easy. Tariffs bit Tesla hard—up to 100% on Chinese EVs and 25% on batteries by late 2024. That’s why they axed the cheap Model 3 RWD in the US; its Chinese LFP didn’t qualify for $7,500 tax credits. Leases worked around it, but sales suffered.

The Tesla LFP battery factory Nevada fixes that. Local cells meet “Made in USA” rules, unlocking credits for future models. But ramp-up takes time—Q1 2026 start means short-term imports linger.

Other hurdles? Skilled labor shortages. Nevada imports talent from California. And supply chains: Lithium comes from Tesla’s Texas refinery, iron from US mines. It’s cleaner but costlier at first.

Wins outweigh: By 2027, costs drop 15%, per analysts. Tesla’s $4.3B deal with LGES for more US LFP backs this up. Rivals like Ford eye similar plants, sparking a US battery race.

Quote from Elon Musk: “Batteries are the backbone of sustainable energy. Nevada’s our proving ground.”

Tesla LFP Battery Factory Nevada: Impact on Electric Vehicles

While the factory starts with storage, EVs loom large. LFP’s lower density suits short-haul cars, but Tesla tweaks designs for better range. Imagine a $30K Model 3 with 300 miles—all US-made.

Past snag: The discontinued Model 3 RWD lost tax perks due to foreign LFP. Nevada cells change that. By 2027, 20% of Tesla’s US EVs could use them, cutting prices $2,000 per car.

Broader ripple: Cheaper batteries mean more EVs on roads. US sales hit 1.2M in 2025; LFP could push to 2M by 2030. It eases “range anxiety” for city drivers—charge overnight, go 250 miles easy.

Tip for buyers: Stick to Tesla’s app for charge limits. LFP thrives at 100%, unlike nickel packs.

The Road Ahead: Expansions and Innovations at the Factory

Tesla doesn’t stop. The Tesla LFP battery factory Nevada ties into a $3.6B Gigafactory upgrade: 100 GWh for 4680 cells and a Semi truck line. LFP could power robotaxis or Optimus bots—compact, safe energy for AI.

Next: Scale to 20 GWh by 2028. Maybe dry coating for denser packs. Partnerships? Deeper CATL ties, but US-focused.

Watch for: Q4 2025 hiring surge. And Battery Tech Online’s LFP roundup for competitor scoops.

This factory sparks a US green boom.

Sustainability Perks of Local LFP Manufacturing

Green goals drive the Tesla LFP battery factory Nevada. No cobalt means no conflict mining. Iron sourcing? Local, low-carbon. The plant recycles 95% water and runs on renewables.

Carbon savings: One GWh of LFP cuts 500 tons of CO2 yearly vs. gas plants. Scaled up, that’s millions saved. Nevada’s geo-thermal ties in, making it energy-self-reliant.

For communities: Cleaner air in Reno valley, where smog dropped 15% since Gigafactory opened. Tesla plants trees—10,000 last year.

Action step: Support local—buy a Powerwall and offset your grid use.

Comparing Tesla’s LFP Factory to Rivals

| Feature | Tesla LFP Nevada | Ford BlueOval Michigan | LGES Michigan |

|---|---|---|---|

| Capacity (Initial) | 10 GWh/year | 35 GWh/year | 20 GWh/year |

| Focus | Storage first, EVs later | EVs like F-150 Lightning | GM and Tesla ESS |

| Tech Partner | CATL equipment | CATL license | In-house |

| Start Date | Q1 2026 | 2026 | 2025 |

| Jobs Added | 500+ | 2,500 | 1,700 |

Tesla leads in speed—built in 18 months. Ford bets big on trucks; LGES diversifies. This table shows why Nevada’s site sets the pace.

Tips for Using LFP Batteries in Daily Life

Got a Tesla with LFP? Or planning one? Here’s how to max lifespan:

- Charge to 100%: Daily full charges build healthy cycles.

- Avoid Deep Drains: Keep above 20% for longevity.

- Cool Storage: Park in shade—heat shortens life.

- Software Updates: Tesla’s app tweaks for optimal performance.

- Warranty Check: 8 years/100K miles standard.

These steps add years to your pack. For more, see InsideEVs on Model 3 LFP.

The Bigger Picture: Tesla LFP Battery Factory Nevada in the EV Revolution

This factory isn’t solo—it’s part of Tesla’s master plan. With Giga Texas and Shanghai, it forms a global net. But Nevada’s US heart beats strongest, dodging trade wars.

Stats: EV adoption hits 18% US market share in 2025. LFP drives affordability, key for mass shift. Tesla’s energy storage? 94% market lead, per Wood Mackenzie.

Challenges linger: Raw material prices fluctuate. Lithium dipped 50% in 2025, but iron stays steady. Tesla hedges with its refinery.

Overall, it’s reassuring: Green tech grows here, creating secure futures.

In Conclusion: Why the Tesla LFP Battery Factory Nevada Changes Everything

The Tesla LFP battery factory Nevada stands as a beacon for sustainable progress. It brings affordable, safe LFP production home, fueling Megapacks, Powerwalls, and soon EVs. From job creation in Sparks to slashing carbon footprints, its ripple effects touch us all. As Tesla ramps to 10 GWh and beyond, expect cheaper green energy and more EVs on roads. This isn’t just a factory—it’s America’s charge toward a brighter, cleaner tomorrow.

What excites you most about local LFP batteries—lower bills, safer cars, or new jobs? Share in the comments!

References

- Tesla Gigafactory Nevada Overview. (2025). Tesla.com.

- Wikipedia: Gigafactory Nevada. (2025).

- Tesla Unveils LFP Plant in Nevada. Battery Tech Online. (2025).

- Tesla Model 3 RWD Discontinued. InsideEVs. (2025).

- LFP Manufacturers Spotlight. Battery Tech Online. (2025).